Plastic recycling at Biffa Polymers

Biffa Polymers is at the forefront of plastic recycling in the UK, operating multiple state-of-the-art plastic reprocessing facilities.

What we do and our capabilities

As a market leader, converting over 190,000 tonnes each year of plastic into high quality recycled polymer we are a key contributor to the UK circular economy.

Redcar

Biffa Polymers at Redcar offers a variety of plastic reprocessing services & were the first in the world to produce rHDPE food grade pellets recycled from post consumers sources and were awarded the Queen’s Award for Innovation.

83,000

tonnes per year rHDPE, rPP

Seaham

This £27.5m state of the art PET plastic bottle recycling facility in Seaham is among the most modern and technically advanced in the world. It is part of our ongoing drive to invest in the UK’s recycling infrastructure and encourage more waste recycling at home.

57,000

tonnes per year rPET

Sherburn

Acquired in 2023 the facility at Sherburn in North Yorkshire processes PET flakes into food grade PET pellets. The site complements our PET capability at Seaham and increases our capacity to produce rPET food grade pellets.

25,000

tonnes per year PET

Our Polymers business is at the heart of the UK’s circular economy, supporting households and brands to increase the amount of plastic which is recycled and then re-used

James McLeary

Managing Director, Biffa Polymers

190,000

plastic recycling capacity in tonnes per year

1.3 billion

Seaham capacity to process beverage bottles into recycled PET

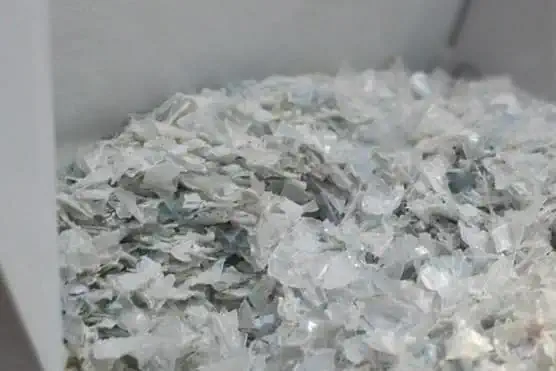

Recycled plastic materials we sell

Biffa Polymers produces a variety of recycled plastics which can substitute the use of virgin plastics, significantly reducing your carbon footprint.

Get in touch

If you would like to discuss opportunities around plastic processing or purchasing any of these recycled plastics, then please complete the enquiry form.

More information on the products we sell

Download our product sheets to find out which recycled plastic product is right for your needs.