What iff cosmetic waste got a makeover?

Cutting down on cosmetic waste

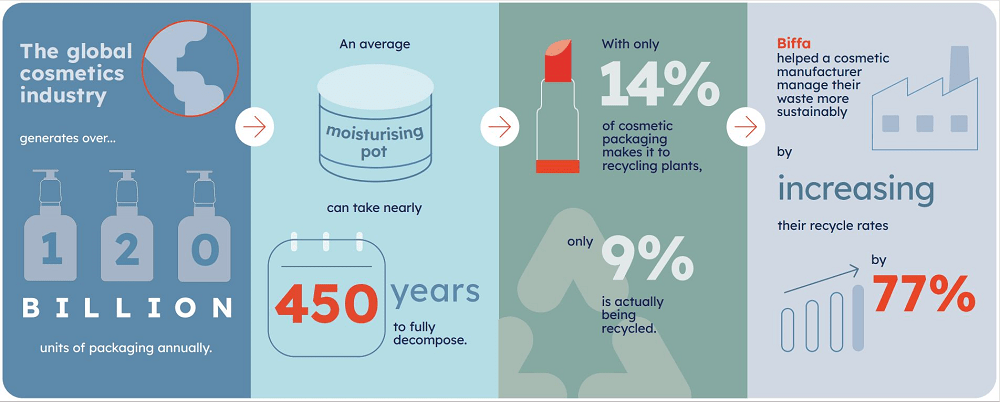

According to the Zero Waste report, the global cosmetics industry generates over 120 billion units of packaging annually, with a significant portion of it not recyclable.

The UK cosmetics industry faces challenges as their product packaging are prone to contamination, and often contain hazardous substances. An average moisturiser pot can take nearly 450 years to fully decompose. These cosmetic products often involve multiple layers of packaging materials such as plastic wrappings, paper inserts, cardboard sleeves, foam, mirrored glass, and other components, sometimes all put together in a single purchase making recycling and sustainable waste management more challenging.

In response to a leading cosmetic manufacturer's aim to improve the circularity of their products and manage their waste more sustainably, we took on the challenge of revolutionising their complex waste streams and consolidating their supply chain. Our objective was to find innovative approaches that could assist them in streamlining their processes, enhance recycling opportunities and significantly reduce waste.

New avenues for effective recycling

The British Beauty Council reports that just 14% of cosmetic packaging makes it to recycling plants, with only 9% actually being recycled. This low rate is because cosmetic products are composed of various materials which are complex and expensive to sort, process and recycle, serving as a barrier for widespread recycling efforts.

By exploring the design of the packaging more closely, we discovered ways to increase the number of materials that can be recycled. This led to a significant improvement; switching from everything being incinerated to a recycling rate of 77% whilst still offering secure product destruction to protect their brand.

Recycling perfume: A fragrant solution

Perfume contains alcohol and various chemicals that can be harmful to the environment and pose health and safety risks if disposed of incorrectly. Additionally, the physical components of perfume bottles also need to be considered. Working alongside our specialist partners we are able to address these issues and find a sustainable solution.

Disposing of hazardous substances:

- To ensure safe disposal of the hazardous waste, Mobile chemists employ a high-pressure press, effectively removing the bulk of the hazardous liquid.

- The liquid is then pumped into storage tanks and blended with other materials that match the hazardous properties.

- The hazardous liquid then moves safely on to distillation to be used for fuel.

Recycling composite packaging and multi-material packaging:

The composite packaging layer and multi-material packaging poses a unique challenge. The core glass structure and the plastic sprayers create a multi-material composition. Biffa has developed a solution to recycle as much as possible.

- Once the hazardous substances have been removed, the packaging is moved to a secondary hopper for a precision 10mm shredding process.

- This is followed by passage through a high-pressure screw wash to eliminate any remaining residues.

- The material is then directed to a dual rotary wash system.

- The resulting wash waters are pumped into holding tanks, awaiting sampling to ensure compliance with discharge standards.

- Once the plastic is thoroughly cleaned of all hazardous materials, it is transported to a separate facility for recycling.

Glass recycling process:

- The glass goes through an impact crusher, vibratory wash and then a sink float.

- The glass is broken down to 30mm and sent to our specialist partner for final processing which goes to remelt or as an aggregate substitute.

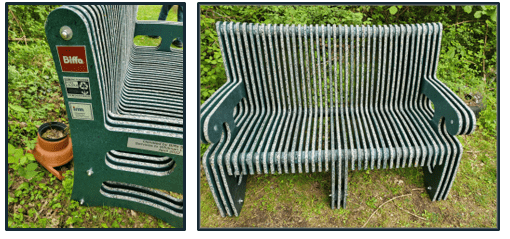

Upcycling beauty: From non-recyclable plastic to furniture

Materials that were previously excluded from recycling streams due to their mixed or contaminated nature are now finding a new purpose. With the recycled materials our innovative partners have developed techniques to create garden furniture, sofas and bins for the manufacturer's office, from materials that would have previously been incinerated.

All plastic components undergo initial shredding, followed by a thorough washing process, and then undergo a final shredding phase to achieve a maximum size of 5mm. The technique meticulously arranges three layers of shredded plastic, with two protective skin layers enveloping a sturdy core. Through a combination of heat and pressure, the plastic expands and transforms. The outcome is a resilient and robust plastic board with a wide range of potential applications.

Composting creams and liquids

All non-hazardous liquids and solids materials from the cosmetics, go through to a composting system for brownfield land remediation, where under controlled conditions, such as temperature, humidity, and aeration, the decomposition process takes place. Composting not only reduces landfill waste but also creates nutrient-rich soil for sustainable agriculture.

The compost system is a typical aerobic process. It involves mixing carbon-based materials with food waste, creating an oxygen-rich environment that enables microbes to break down organic materials. This process reduces greenhouse gas emissions and produces compost known as CLO, which can be used to restore degraded lands.

All products and mixtures are tested and assessed, using our onsite lab, with and are validated weekly by an EA accredited lab and a secondary DEFRA lab. The product that is manufactured is tested in batches and stabilised before being applied to land.

Ready to take the next step towards a greener future?

Contact us today to explore how our tailor-made solutions can benefit your business and contribute to your sustainability goals.